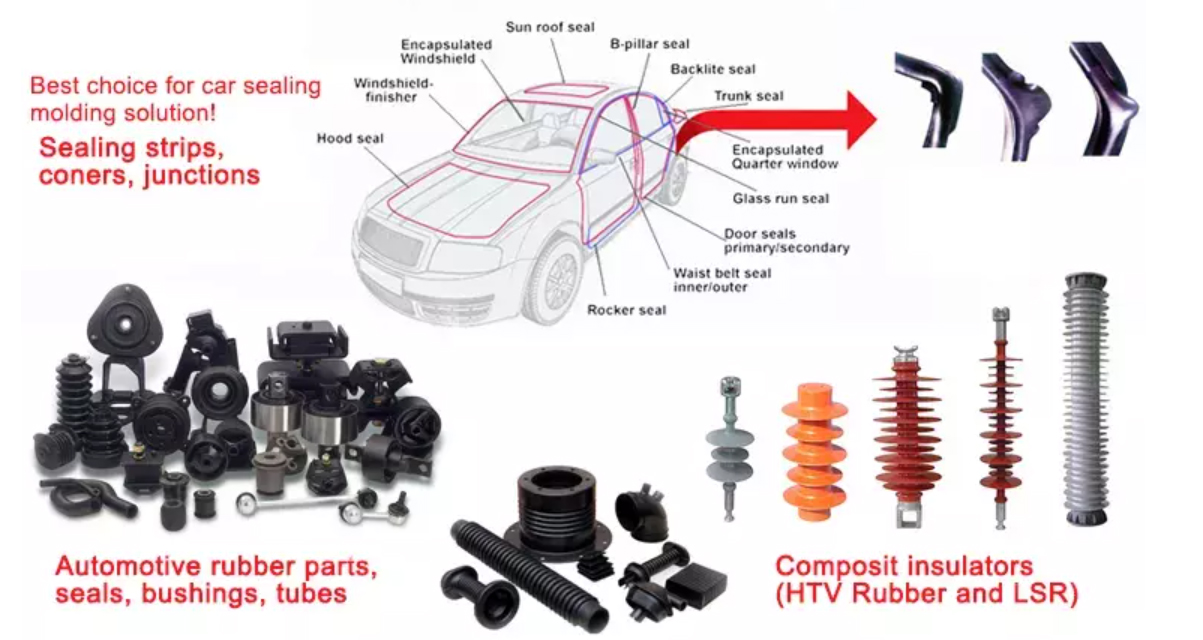

Custom Bonded Rubber to Metal Parts

Product Parameters

The sizes , color and materials can be customized .

Certification:CE,ISO9001,LFGB,FDA,ROHS.

Working Temperature : -40℃~240℃

Elongation rate : 300%

Hardness: 10°~90° Shore A

Features

1.Excellent sealing and damping

2.Good water resistance

3. Good anti-aging

4.Good anti- ozone

5.Good oil-resistant

6.Great pressure resistant

7.High and low temperature resistant

Advantage

1. Drawing:2D or 3D draiwng

2. Free samples provided , accept trial order and mix order

3. Replace the qualified products in the next order once you found the

defectives when you get goods.

3. Regular customers kept being informed our latest products with free samples and favorable prices.

4. Welcome to tests: SGS, flame retardant and UV resistance etc .

5. Strictly quality contral entire process .

6. Punctually delivery and thoughtful sales service

7. Welcome to custom sizes , colors and special designs .

8. Welcome OEM&ODM services absolutely

9. Sales team supply the soonest feedback on your enquires, questiones and complaints.

|

NBR |

Good chemical resistance to mineral oils and greases, hydraulic oils H, HL, HLP, non-inflammable hydraulic pressure fluids HFA, HFB, HFC to approx. +50°C and water to max. +80°C |

|

HNBR |

HNBR is obtained by fully or partially hydrogenating NBR. It leads to considerable improvement in resistance to heat, ozone and ageing, and gives it very good mechanical properties, e.g. good resistance to wear. The media resistance compares to that of NBR. HNBR has a good resistance to some refrigerants. The temperature application range is from -30°C to +150°C. |

|

EPDM |

Good resistance to hot water and steam, detergents, caustic potash solutions, silicone oil and greases, many polar solvents, and many diluted acids and chemicals, along with a high level of ozone resistance. EPDM materials are totally unsuitable for use with all mineral oil products (lubricants, fuels). |

|

FKM |

Good chemical resistance to mineral oils and greases, synthetic oils and greases, engine, transmission and ATF oils to approx. +150°C, fuels, non-flammable hydraulic pressure fluids HFD, aliphatic, aromatic and chlorinated hydrocarbons, water to max. +80°C, excellent resistance to weathering, ozone and ageing, very low gas permeability (and therefore excellent for vacuum application) and resistance to a wide range of chemicals. |

|

VMQ |

Good resistance to water (up to 100 °C), aliphatic engine and transmission oils, animal and plant oils and fats. VMQ is generally not resistant to fuels, aromatic mineral oils, steam (short term up to 120 °C possible), silicone oils and greases, acids and alkaline compounds. |

FAQ

1.Q: Are you a manufacturer?

A: Yes, we are a manufacturer that special for producing and exporting of rubber products . Welcome to visit our factory.

2.Q: Can you supply the sample ?

A: Yes , We can supply the sample for free , but customers need to pay the freight.

3.Q: Can you arrange the shipment?

A: Of course, we have a fixed shipping agent who can get the best price from most shipping companies and provide professional services.

4.Q: How long is your lead time ?

A: If available, it usually takes about 7 days. if the goods are not in stock, that will be based on the order quantity . Our production capacity is 10,000PCS/ month.

5.Q: How can we get the quotation?

A: Please provide the drawing or product specifications, such as material, size, shape, etc., so that we can quote you the best quotation.

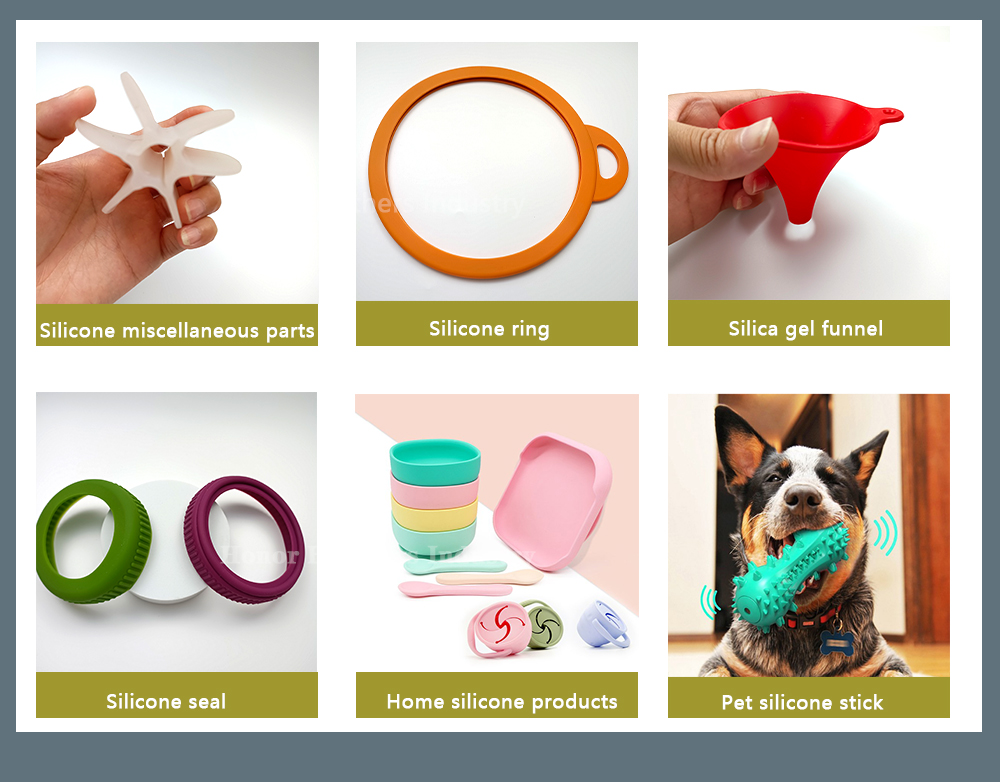

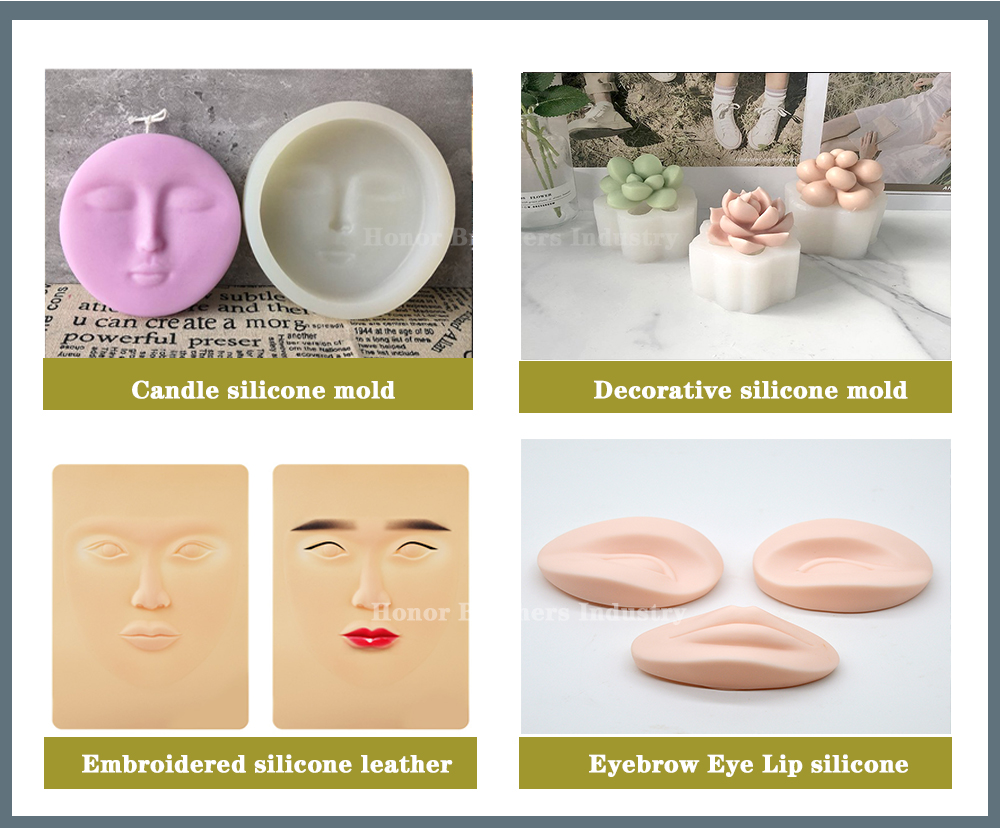

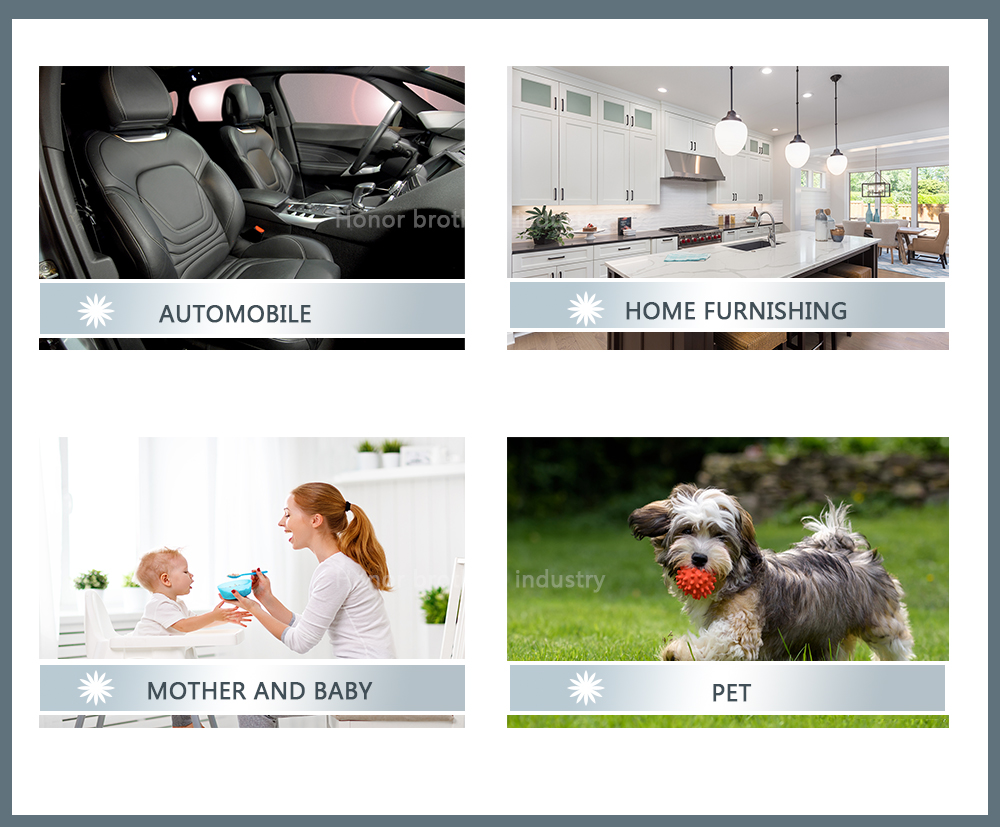

Application

Electron components, Medical equipment, Home appliance, Mechanical equipment, Office facilities, Aviation, Construction, Automobile, Anti-Ski.

Product View